Important Guide to Searching For Reliable Commercial Refrigerator Repair Solutions

Important Guide to Searching For Reliable Commercial Refrigerator Repair Solutions

Blog Article

Repairing Business Refrigeration Fixing: Strategies for Quick and Effective Fixes

Comprehending the usual issues that torment industrial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in quickly identifying and correcting problems. As we browse via the complexities of repairing industrial refrigeration fixing, we will discover the vital strategies for fixing issues effectively, ensuring that companies can maintain optimum air conditioning efficiency and decrease downtime.

Common Industrial Refrigeration Problems

Commercial refrigeration systems commonly run into a range of functional problems that can disrupt their effectiveness and performance. One common problem is inappropriate temperature control, which can bring about food putridity and waste if not quickly attended to. This issue may stem from problems with the thermostat, evaporator fan, or condenser coils, needing detailed examination to identify the source. One more common problem is insufficient air movement, usually created by obstructions in the vents or a malfunctioning follower. Poor air movement can bring about temperature level disparities within the fridge or freezer, affecting the high quality and safety of stored products.

Furthermore, refrigerant leaks pose a considerable problem as they not just impact the air conditioning ability of the system however likewise contribute to environmental damage. Identifying and fixing leakages immediately is essential to avoid additional damage and make sure compliance with guidelines. Furthermore, unclean condenser coils can impede warmth transfer, compeling the system to work tougher and consume even more energy. Regular cleaning and maintenance can aid avoid this concern and lengthen the life expectancy of the refrigeration system.

Diagnostic Devices and Techniques

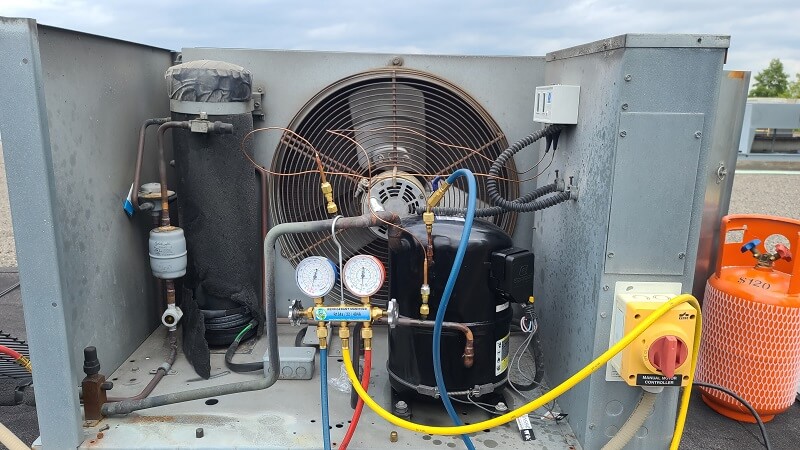

Efficient troubleshooting of industrial refrigeration systems counts greatly on making use of specialized diagnostic tools and techniques to identify and resolve underlying problems successfully. One vital analysis device is the multimeter, which assists professionals measure voltage, present, and resistance in various parts such as compressors, motors, and defrost heaters. Thermometers are likewise essential for evaluating temperature differentials throughout the system to determine prospective issues like refrigerant leaks or improper airflow. Additionally, leak detection devices like electronic leak detectors or ultraviolet dye kits are crucial for locating cooling agent leakages that can bring about system inadequacies.

Methods such as stress screening utilizing manifold assesses can establish if the system has the correct cooling agent fee and recognize any kind of leakages. Aesthetic examinations of elements for indications of corrosion, ice, or wear accumulation are also fundamental in identifying problems. Information loggers can be utilized to keep track of system efficiency over time and find trends that might indicate recurring troubles. By combining these analysis devices and techniques, professionals can effectively troubleshoot industrial refrigeration systems and supply quick and specific repairs, minimizing downtime and ensuring optimum system performance.

Quick Fixes for Refrigeration Troubles

When faced with refrigeration troubles, professionals can apply quick fixes to deal with common concerns swiftly and efficiently. If the refrigeration device is not cooling down properly, checking and readjusting the thermostat settings might give a fast option before even more thorough troubleshooting is required. By implementing these fast repairs, specialists can deal with usual refrigeration troubles efficiently and maintain industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Carrying out an aggressive upkeep schedule is essential for making sure the durability and optimum performance of business refrigeration systems. Routine upkeep not only aids stop costly failures however additionally makes sure that the devices runs efficiently, conserving power and lowering overall operating prices. Here are some preventative upkeep suggestions to maintain commercial refrigeration systems running efficiently:

Inspect and Replace Filters: Dirty filters can limit air flow, making the system work tougher and potentially triggering damage. Examine and replace filters frequently to avoid issues.

Inspect Seals and Gaskets: Dripping seals and gaskets can lead to temperature level fluctuations and energy wastefulness. Examining and changing harmed seals can assist keep constant temperatures.

Professional Assistance and Solutions

To maintain the ideal performance attained with regular preventative maintenance, looking for expert support and solutions for commercial refrigeration systems is essential. Professional professionals possess the competence and specialized knowledge required to detect and deal with intricate problems efficiently. When encountering tough refrigeration problems, depending on professional support can conserve both time and money in the future.

Expert solutions provide benefits such as accessibility to advanced devices and equipment, ensuring that fixings are performed properly. Additionally, professionals are trained to comply with market laws and safety criteria, reducing the threat of accidents and making sure conformity with lawful demands.

Conclusion

Finally, repairing business refrigeration repair service needs a methodical method to recognizing typical issues, making use of analysis tools and strategies, implementing fast solutions, and prioritizing preventative maintenance. Specialist support and solutions might be necessary for more complicated troubles - Toronto commercial refrigerator repair. By complying with these approaches, businesses can ensure their refrigeration systems run successfully and effectively, reducing downtime and prospective losses

Recognizing the common issues that pester industrial refrigeration systems and having a toolkit of analysis strategies at your disposal can make all the distinction in promptly recognizing and treating troubles.Reliable troubleshooting of commercial refrigeration systems relies heavily on utilizing specialized diagnostic devices and techniques to identify and fix underlying problems effectively. By combining these diagnostic tools and techniques, specialists can efficiently troubleshoot industrial refrigeration systems and supply quick and accurate repair work, reducing downtime and making sure ideal system performance.

By executing these quick fixes, technicians can resolve usual refrigeration troubles efficiently and keep industrial refrigeration systems running efficiently.

In addition, specialist support can assist expand the life expectancy of commercial refrigeration systems by recognizing prospective problems prior to they click to find out more escalate.

Report this page